R&D

Research Center Status

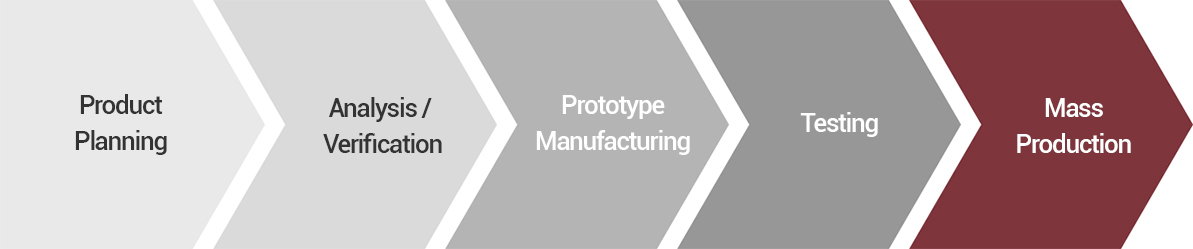

Research Process

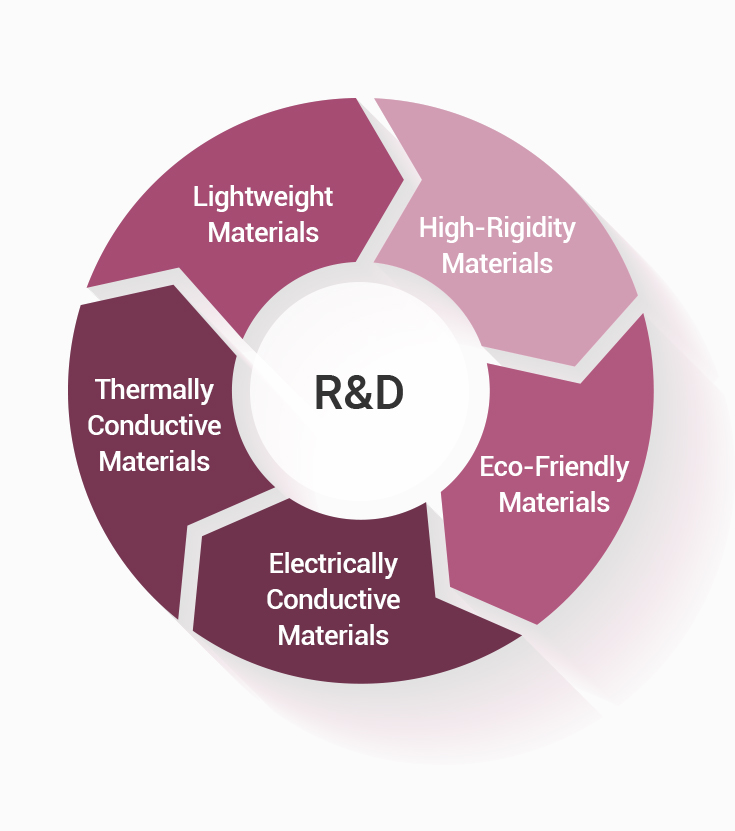

SHINIL Chemical Industry Co., Ltd.'s R&D Center examines the feasibility of development for new products, sets quality and reliability targets, and carries out prototype manufacturing. Moreover, it has selected five key focus areas to actively work towards the development of convergent materials that fulfill customer needs, continuously putting efforts into satisfying the ever-evolving demands of the market.

SHINIL Chemical Industry Co., Ltd.'s R & D 5 Key Focus Areas

Research and Development (Research Center Status)

CAE

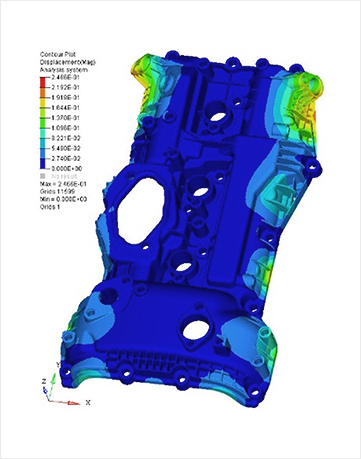

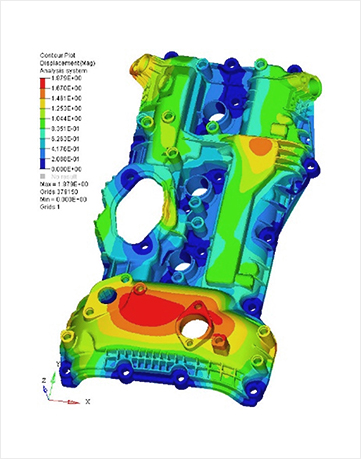

We provide product optimization and structural stability using CAE to accompany our plastic products.

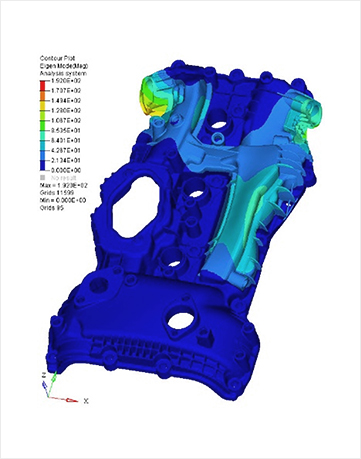

Structural Analysis

01. Static Analysis

Assessment that forms the foundation for all analysis, evaluating deformations and strength stability under external loads.

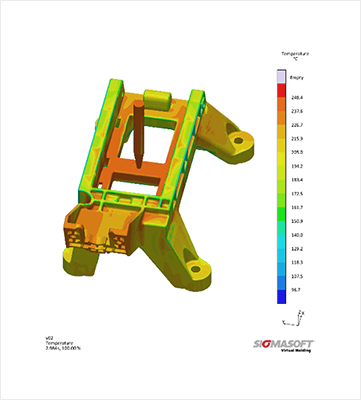

02. Thermal Analysis

Prediction of equipment or component design regarding expansion/contraction and normal operation within the expected temperature range through heat.

03. Vibration Analysis

Assistance in design through Modal/Harmony analysis to prevent noise and fatigue failure that can be caused by vibration.

Injection Analysis

01. Fluid Analysis

Predicting the flow of resin being filled into the mold through numerical analysis, forecasting and progressing issues such as short shots, voids, weld lines, and gate optimization.

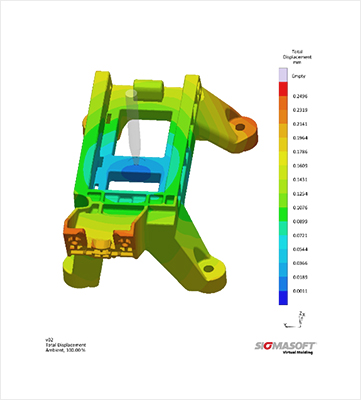

02. Flow/Deformation Analysis

Direction for product and mold design by predicting deformations caused by residual stress during molding and cooling, aiding in product quality improvement and development period reduction.